Bulk Material - Silicone Gel

In principle different materials can be used as bulk material. CRW is specialist in silicone gel materials.

Silicone gel belongs to the group of RTV-2 silicone rubbers, which are room-temperature-vulcanisable materials consisting of two components. Silicone gel is much softer and more deformable than silicone rubber. The low modulus of silicone gel results from its low cross-link density. The material has a high tensile strength and a high stress relaxation.

One component contains a polydimethylsiloxane with vinyl end groups, a platinum catalyst, and optionally further additives. The second component consists of a cross linking agent, which is either a polymethyl hydrogen siloxane or a copolymer thereof with a polydimetylsiloxane.

Additive - Nonlineare Conductivity

The used additives are inorganic substrates with metal oxide coating and different dopants (Figure 1). The nonlinear electrical properties are adjusted by the introduction of dopants.

Figure 1: Macroscopic view of additive.

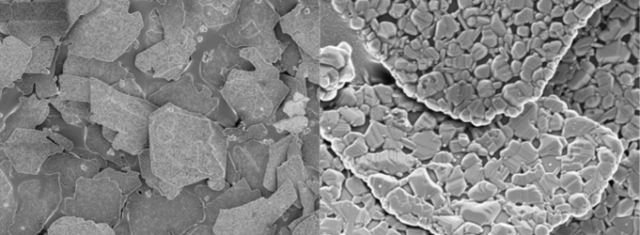

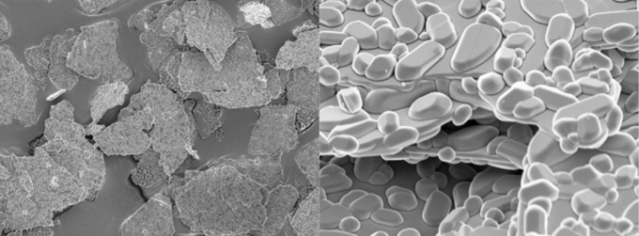

Figure 2: SEM image of filler particles.

Figure 2 shows the particles with a magnification of 1 k (left) and 10 k (right). The scanning electron microscope (SEM) images shows different particles. The selected doping has a significant influence on the formation of the boundary layer of the particles. At a magnification of 1 k, the platelet-shaped structure is clearly visible. The particles have irregular sizes in the range between 5μm and 35μm. The image with 10 k magnification illustrates the granular coating of the particles.

Additive - Compressible Compound

For the design of insulation systems with a wide operation temperature range, the thermal expansion of the material has to be considered. To compensate this expansion a silicone gel with hollow and flexible micro spheres (HMS) can be used.

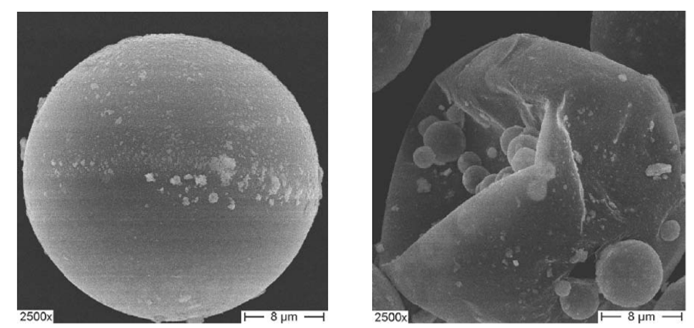

Figure 3: Hollow microspheres under normal pressure (left) and high pressure (right).

The hollow spheres (Figure 3) have a cover based on a polymer and are filled with gas. They are elastically deformable, so they change their volume under the influence of pressure. The Figure gives an impression of the expanded, respectively compressed HMS.